How Do Portable Tire Inflators Work

Simply put, the working principle of the portable air pump is to convert electrical energy (from a lithium battery or 12V on-board power supply) into mechanical energy through a high-speed DC motor. This motor drives the piston inside the cylinder to reciprocate, quickly compressing the inhaled air and forcing it into the tire through a one-way valve. In order to ensure safety and accuracy, the built-in digital pressure sensor (transmitter) of the machine will keep an eye on the back pressure; once the PSI inside the tire reaches your preset target value, the control circuit will instantly cut off the power supply and automatically stop inflation to prevent overcharging.

To fully understand this process, we can break down its operating logic into four key stages: energy input, mechanical compression, airflow directional delivery, and intelligent monitoring.

Input Of Electric Energy

- Lithium battery: The pursuit is to get rid of the shackles of the cable, the core is the high-density chemical energy stored in the battery pack.

- 12V DC car interface: directly take electricity from the electrical system of the vehicle.

Once the device is started, electrical energy is pumped into the high-speed DC motor. To be honest, the efficiency of the motor is the top priority of the whole link, which directly determines the speed at which the equipment converts electrical energy into mechanical torque. If the motor selection is not good, the compression efficiency of the next stage will be out of the question.

Compression Mechanism: Piston And Cylinder

Inside the housing of the air pump, a DC motor is connected to a miniature crankshaft. As the motor rotates at high speed, it drives the precision machined piston to move up and down in the cylinder.

- Intake stroke: When the piston moves down, a transient vacuum is created, which draws atmosphere into the cylinder through the intake port.

- Compression stroke: When the piston backs up, it will vigorously compress the air volume in the cylinder, thereby significantly increasing the pressure.

This mechanical cycle is repeated thousands of times per minute, creating a continuous stream of high-pressure air. From the perspective of research and development, the sealing and wear resistance of the cylinder are often the ceilings that determine the life of the product.

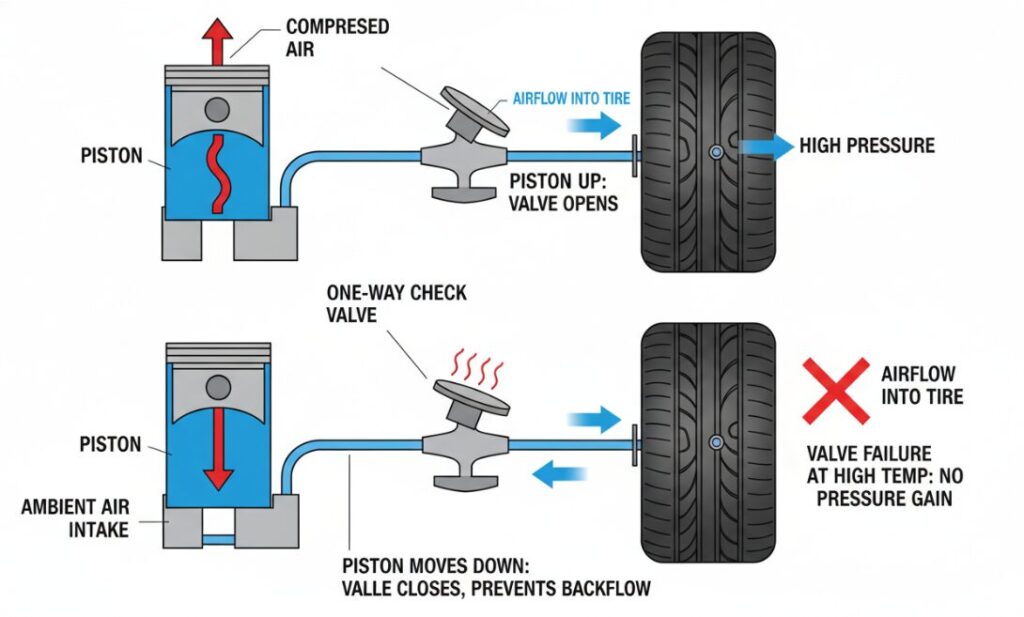

Directional Airflow: One-Way Check Valve

There is a very critical but easily overlooked component in this system: the one-way check valve. Its core task is to ensure that compressed air can only flow in one direction-that is, only into the tire, not back.

When the piston compresses air, the pressure will open the valve, allowing air to flow through the air pipe and into the tire valve. When the piston moves down to draw in new air, the check valve will close immediately. This can effectively prevent the high-pressure air that has formed in the tire from flowing back to the cylinder, thereby maintaining the continuous accumulation of pressure. If this valve deforms or fails at high temperatures, you will find that the air pump has been ringing, but the tire pressure has not risen at all.

Precise Control: Sensors And Automatic Shutdown

The high-quality air pump and cheap “pump” separate, in fact, the level of integration of digital pressure sensors. This sensor is located inside the gas circuit and acts as the “brain” of the device “.

When air is pressed into the tire, the sensor will continuously measure the “back pressure” in the trachea and convert it into an electrical signal that the control circuit can recognize.

- Real-time monitoring: The digital display screen will update the current PSI value in real time according to the data returned by these sensors.

- Automatic shutdown: The user presets a target pressure. Once the sensor detects that the PSI inside the tire reaches the critical point, the control circuit will immediately cut off the power to the DC motor. According to my experience, excellent algorithm compensation can control this shutdown error within 0.5 PSI, which is not only to protect the tire from being inflated, but also to maintain the safety of the tire structure.

Author: David Miller

“Hi, I’m an automotive gear specialist with over a decade of experience in vehicle maintenance and tool engineering. I’m passionate about demystifying the technology behind the tools we use every day. In this article, I’ve broken down the internal mechanics of portable tire inflators—from the high-speed DC motor to the precision of digital transducers—to help you understand the science that keeps your tires at the perfect pressure for every journey.”

Carsun

Carsun